Edwards Engineering was formed in Perth in 1969. Our founder, Henry Edwards, saw an opportunity to pursue an engineering services business focused on grain handling and drying.

Edwards began installing grain handling equipment across Scotland including the Olding, Carier and Wilder equipment ranges. We supported installations with annual maintenance services.

By the middle of the decade, Edwards was delivering projects to the distilling industry including Inverhouse Distillers, Highland Distillers and Scottish Grain Distillers.

Edwards delivered many hydro-power related infrastructure projects for Scottish Hydro Electric at locations including Cruachan Dam and Loch Awe.

Grain handling facilities continued to get larger and Edwards designed and installed equipment from all the major manufacturers for grain processors across Scotland.

By the end of the 1970s, Edwards was firmly established as the leading engineering firm in the agriculture market. The company invested in widening general engineering capability and was forging relationships in the whisky distilling industry.

Through the 1980s, Edwards expanded into structural steel with investment in our workforce in Perth. This capability supported the expanding manufacturing base in Scotland and the business grew its installation and commissioning skillset.

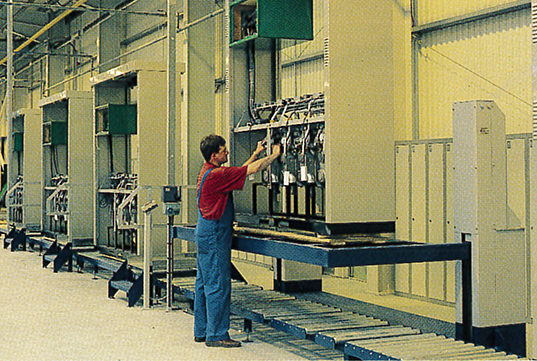

Edwards’ engineering skillset meant that strong relationships were developed with the maltings industry across Scotland, and this endures to the present day. Customers included Moray Firth Maltings, Gleneagles Maltings and Munton and Fison.

Edwards played a major role in construction of the McDiarmid Park stand in Perth. This included full fabrication and erection of the 10,000 seat stadiums at the home of the St Johnston Football Club.

Ongoing engineering support provided to industrial firms including Hamlyn Mining, Halliburton and Highland Spring.

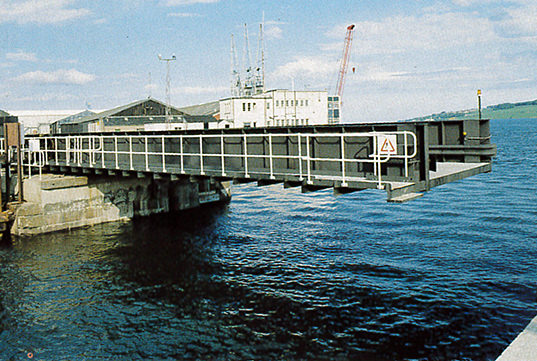

The 1990s saw Edwards invest in our design and drawing office capability with the adoption of technology as it developed to support the engineering industry. We built on our relationships with Port Authorities and expanded to support the construction and maintenance of infrastructure. The firm maintained expertise in grain handling and drying as technological advancements were introduced by the equipment manufacturers.

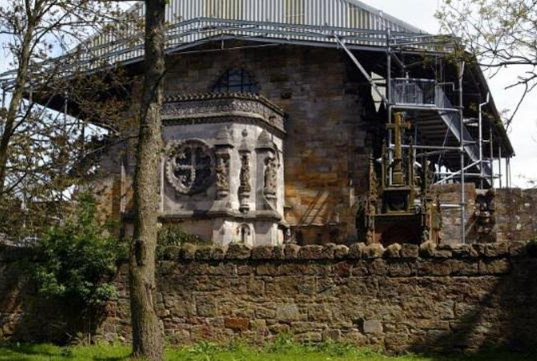

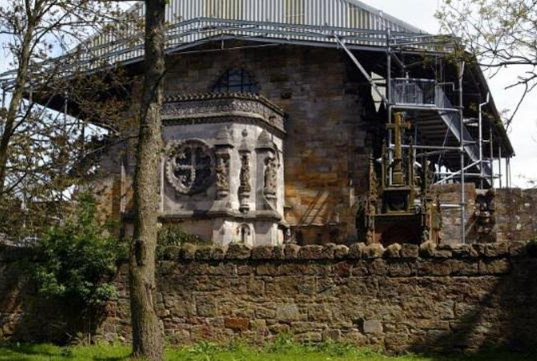

Rosslyn Chapel restoration.

The company has considerable experience with various bridge types including fixed, swing, and bascule counter-balanced designs. The bridge pictured, in Dundee harbour, is an example of a rail mounted extending design.

The 2000s saw Edwards’s deep malting industry expertise develop through close relationships with industry leading processors. Our ability to support major infrastructure projects continued.

Edwards continued to develop its ability to respond to industrial customer requirements with significant capability to support major shutdown works.

The programme to construct and upgrade the schools facilities in the Perth area was a major project that Edwards helped to deliver. We fabricated and installed the structural steel for six schools.

Recent years have seen Edwards continue to broaden our customer base while investing in our team to produce a flexible and widely skilled workforce. We have developed a strong footprint in the Environmental market, delivering projects in recycling and waste treatment. The scale of projects the company takes on has grown both in complexity and importance for our customers.

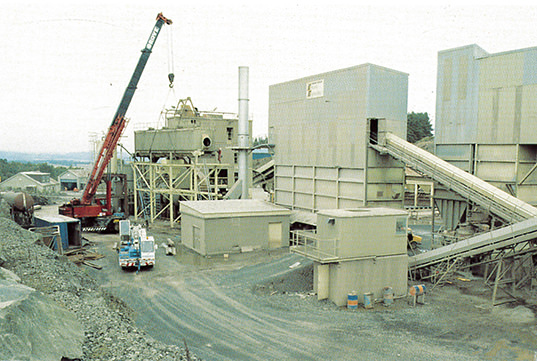

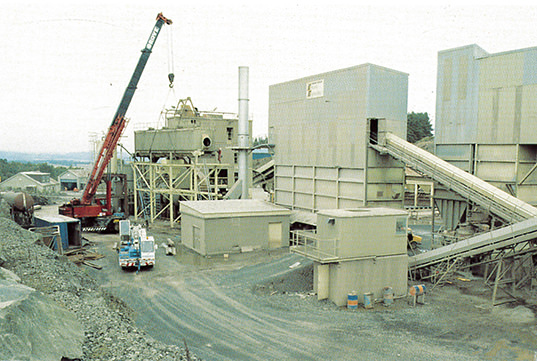

In 2011, East of Scotland Farmers installed Europe’s largest malting barley grain dryer. At Coupar Angus, the Cimbria dryer is capable of processing and drying 40 tonnes per hour of malting barley.

Three years later, Edwards supported a major food industry manufacturer through an 18 month design and installation project in Fife. This involved grain intake, storage and blending capability upgrade.

Edwards recently supported Bairds Malt to deliver a major refurbishment and supported Crisp Malt in completing a major structural upgrade of its Portgordon facility. Read our case study to learn more.

Edwards Engineering helps complete the £37m major upgrade of the Superglass plc glass wool insulation production facility in Stirling. Read our case study to learn more.